161 Products

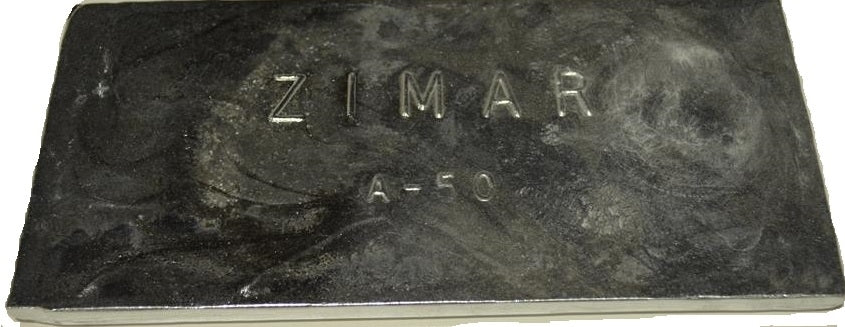

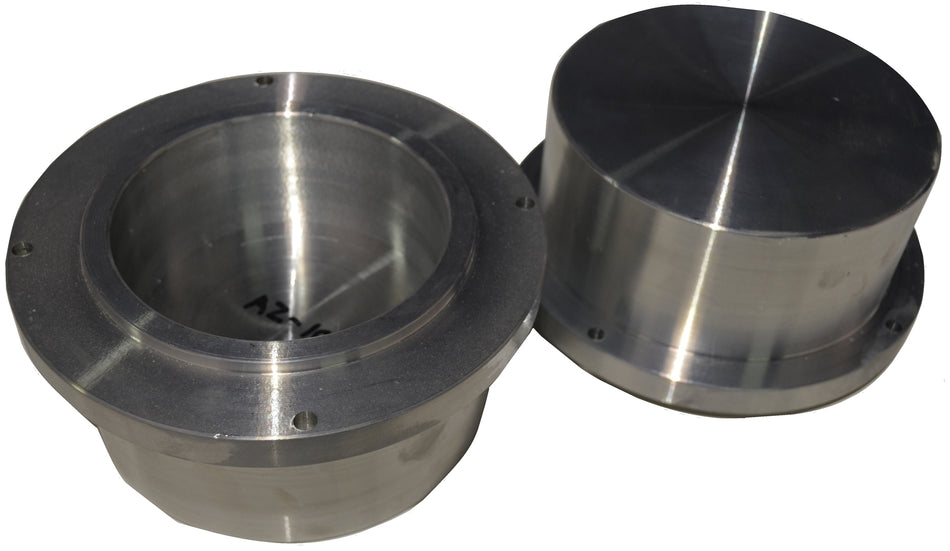

Zincs

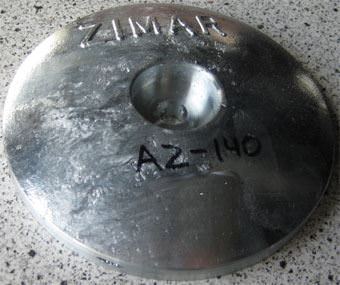

Zimar zinc anodes are the best zinc anodes for cathodic protection in the industry! Deep Blue Yacht Supply offers the best price in the world on these key boating parts. Deep Blue Yacht Supply is able to ship our zinc anodes for boats across the globe! You won't find a better price on the best boat zinc anodes in the marine industry. There is a reason that most discerning boat owners use Zimar zinc anodes for their cathodic protection. Lowest prices and best quality boat zincs including:

- Shaft zincs

- Rudder zincs

- Plate zincs

- Shaft nut zincs